The DTF Gangsheet Builder is immensely transforming the DTF printing process, enabling users to create stunning designs for custom apparel with ease and efficiency. This innovative tool streamlines the gangsheet layout design, helping enthusiasts and professionals alike to maximize their printing potential. By optimizing DTF printing techniques and applying best practices for DTF, users can achieve high-quality outputs with minimal waste. In this guide, we will share essential DTF printing tips and delve into the functionalities of DTF printing software that can enhance your production workflows. Get ready to elevate your designs and customer satisfaction with our expert insights into maximizing your DTF Gangsheet Builder experience!

Direct to Film (DTF) technology has drastically changes the landscape for customizing textiles, allowing for the rapid and detailed application of prints. The DTF gangsheet generator is a crucial component in this modern printing technique, simplifying the arrangement and printing of multiple designs at once. Harnessing effective gangsheet layouts not only enhances material usage but also boosts production efficiency, making it ideal for small businesses and large operations alike. As we explore various approaches to optimize DTF printing, including strategic layouts and selecting the right software, you’ll discover how to refine your crafting process for better results. This introduction highlights the importance of understanding and mastering DTF tools for achieving superior print quality and streamlined production.

Optimizing DTF Gangsheet Builder Performance

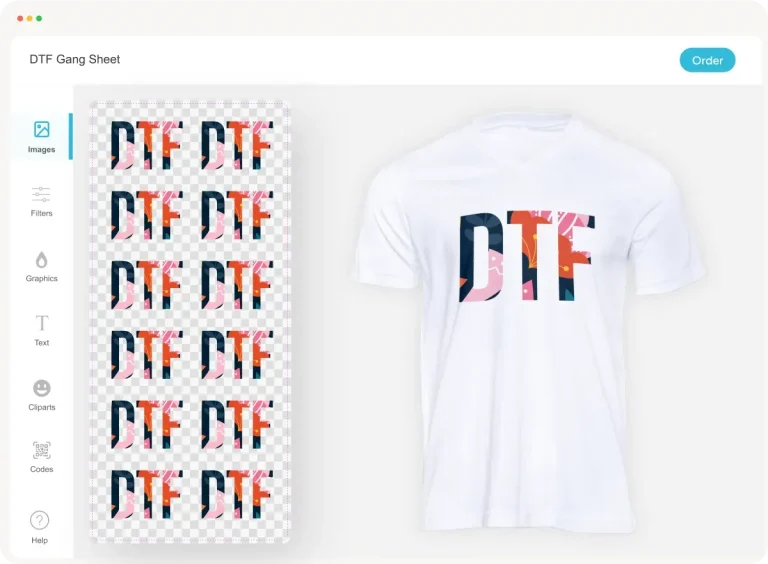

To get the most out of your DTF gangsheet builder, it’s crucial to focus on optimizing every aspect of the process. Start by ensuring your designs are well-prepared. This includes using high-resolution images set at 300 dpi, which significantly enhances clarity and quality. Utilize your design software’s tools effectively to create a gangsheet layout that maximizes space while maintaining the integrity of your designs.

Additionally, familiarize yourself with the features of your DTF gangsheet builder. Understanding its capabilities—like automatic positioning and color matching options—can save time and improve efficiency during printing. Regularly updating your software can also introduce improvements and features that facilitate better outputs and more streamlined workflows.

Key Strategies for Effective Gangsheet Layout Design

Effective gangsheet layout design is paramount in DTF printing, as it directly impacts material usage and print quality. Start by layering your designs based on color similarity to minimize ink usage and improve the vibrancy of colors on fabric. Grouping colors can significantly reduce production time as well, since similar ink colors can be applied in fewer passes.

Incorporating space-saving techniques is crucial as well. Experiment with different arrangements and orientations of designs to find the most efficient use of the gangsheet. Consider using templates or guides within your software that allow for precision in creating various layout configurations—this aids in achieving an optimal balance between aesthetics and resource management.

Best Practices for DTF Printing Success

Implementing best practices is vital for successful DTF printing. One of the most effective strategies is to perform regular maintenance on your printing equipment. Regular checks and cleanings of both the printer and heat press components will help keep your print quality consistent and prevent mechanical issues.

Furthermore, consider performing frequent test prints to calibrate your print settings accurately. Adjustments based on these tests can significantly enhance quality and lead to smoother operations. This proactive approach in maintaining equipment and checking settings lays a strong foundation for high-quality end products and satisfied customers.

Importance of Using Quality DTF Printing Software

The choice of DTF printing software plays a significant role in the overall printing process. Using software specifically designed for DTF applications can streamline your design workflow by automatically positioning images and optimizing the gangsheet. The right software simplifies the complexities of design management, allowing for faster turnaround times.

Also, good software provides extensive tools for color management and design adjustments. This software can help you achieve consistent and accurate results every time, which is crucial for maintaining customer satisfaction. Integrating advanced features from reputable software can propel your DTF printing efficiency to new heights, ensuring that you remain competitive in the market.

Testing for Quality Assurance in DTF Printing

Testing is an essential component of maintaining quality in DTF printing. Regular test prints allow you to assess various factors such as color accuracy, design placement, and adhesion to the substrate. This trial phase is essential for identifying issues early on, minimizing waste, and ensuring that the final products meet your standards.

Moreover, utilizing feedback from these test prints helps in making informed adjustments to your printing settings, such as temperature and speed. Establishing a routine for testing not only fine-tunes your process but also fosters continuous improvement, elevating the standard of your output with each production run.

Enhancing Customer Satisfaction through Color Matching

Color matching is a key part of achieving customer satisfaction in DTF printing. Implementing accurate color profiles in your design software ensures that the colors you envision during the design phase translate effectively to the printed product. This attention to detail builds trust with clients who expect consistency and precision in their printed items.

In addition, regularly reviewing and calibrating your printer’s color settings helps maintain alignment between design output and final prints. By possessing a deep understanding of color management within your DTF printing process, you can provide clients with high-quality results that meet and exceed their expectations, reinforcing their loyalty to your services.

Frequently Asked Questions

What tips can help optimize DTF printing with a DTF Gangsheet Builder?

To optimize DTF printing using a DTF Gangsheet Builder, focus on efficient gangsheet layout design by strategically arranging designs to utilize space effectively. Group similar colors to minimize ink costs and employ programmed layouts to maximize the number of designs per sheet without compromising quality.

How can I improve my gangsheet layout design for DTF printing?

Improving your gangsheet layout design involves careful planning. Use design software that allows for optimized layout arrangements, ensuring designs are appropriately sized and grouped. Efficiently packing designs on the sheet reduces waste and enhances production efficiency in DTF printing.

What are the best practices for DTF printing using a gangsheet builder?

Best practices for DTF printing with a gangsheet builder include using high-quality DTF-specific inks and films, performing regular test prints to fine-tune temperature and speed settings, and managing color profiles in your design software for accurate color matching.

What software is recommended for efficient DTF gangsheet creation?

For creating efficient DTF gansheets, software applications like Adobe Illustrator and CorelDRAW are highly recommended. Additionally, utilize DTF-specific printing software designed to automatically optimize design placements on gang sheets to enhance the printing workflow.

How does material quality impact DTF printing results when using a gangsheet builder?

Material quality is critical in DTF printing outcomes. Using high-quality DTF-specific films and specialized inks enhances adhesion and durability, which are essential for producing high-quality and long-lasting prints with your DTF gangsheet builder.

Why is regular maintenance important for DTF printing and gangsheet builders?

Regular maintenance is vital for ensuring your DTF printing and gangsheet builders operate optimally. Routine cleanings and performance checks prevent equipment failures such as printhead clogs, ensuring consistent output quality and reducing costs associated with reprints.

| Key Points | Details |

|---|---|

| Understanding Gangsheet Layout | Efficiently arrange designs to minimize waste and reduce ink costs. |

| Software and Tools | Use reliable design software and tools specifically for DTF printing. |

| Material Considerations | Invest in high-quality DTF-specific inks and films for better adhesion. |

| Testing and Adjustments | Run regular test prints to evaluate and adjust output settings. |

| Color Matching | Implement specific color profiles in design software for accurate prints. |

| Maintenance | Schedule regular cleaning and checkups for printers and equipment. |

| Additional Resources | Engage with online communities and stay updated with the latest trends. |

Summary

DTF Gangsheet Builder is an essential tool for anyone looking to optimize their DTF printing process, ensuring high-quality results and customer satisfaction. By following efficient layout strategies, leveraging specialized software, using high-quality materials, and performing regular maintenance, you can streamline your printing workflow. Engaging with online resources and staying current with industry developments will keep your skills sharp and enhance your overall printing experience. Emphasizing these aspects will not only improve print quality but also fortify your reputation in the competitive world of custom apparel printing.