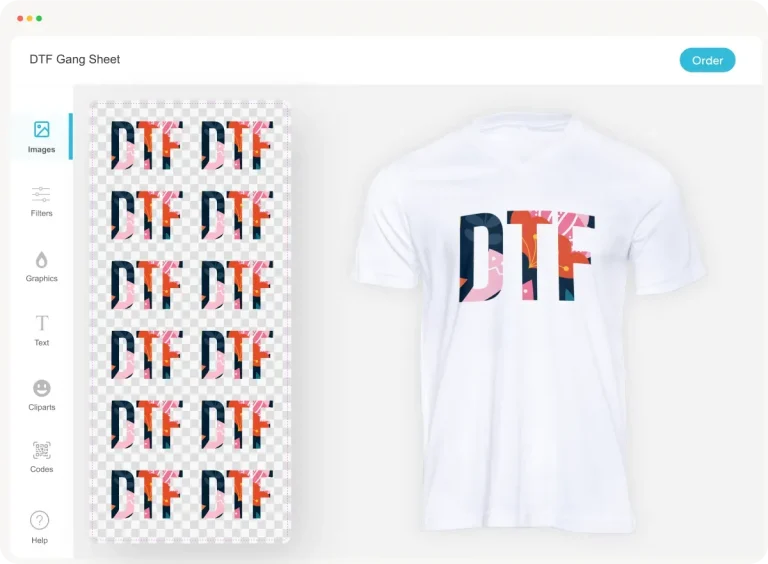

The **DTF Gangsheet Builder** has emerged as a cornerstone tool for enthusiasts in the realm of Direct-to-Film (DTF) printing, a technique that has revolutionized the way we think about printing on fabric. This innovative builder not only optimizes the layout of designs but also enhances the efficiency of producing high-quality prints with vibrant colors and intricate details. By allowing multiple designs to be printed simultaneously on a single film, the DTF Gangsheet Builder significantly reduces wasted materials and printing costs. In this article, we will delve into essential tips for utilizing the gangsheet effectively and explore common pitfalls to avoid in your printing endeavors. Elevate your DTF printing skills and discover how to create stunning prints through the art of gangsheet building.

When discussing the **DTF Gangsheet Builder**, it’s important to recognize its critical role in the broader context of fabric printing techniques. Direct-to-Film printing stands out in the textile industry for its cost-effectiveness and ability to produce high-quality transfers, making it a favorite among producers and creators alike. The process of designing gang sheets ensures that you can maximize your productivity by aligning multiple artwork pieces on one sheet, which is particularly beneficial for small to medium jobs. Understanding key strategies and common mistakes associated with this method can enhance your printing quality and streamline your workflow. By leveraging intelligent design and layout tools, you can achieve remarkable results in the world of DTF printing.

Understanding DTF Printing Techniques

DTF printing signifies a significant leap in the world of textile printing, merging creativity with technology to produce remarkable results. Unlike traditional methods such as screen or direct-to-garment (DTG) printing, DTF employs a specialized film that captures vivid designs, which are subsequently transferred to various fabric types through heat and pressure. This innovative technique has garnered popularity due to its ability to produce high-quality prints swiftly and efficiently, making it a go-to option for many designers and businesses.

The advantages of DTF printing extend beyond just vibrant results; they also encompass versatility and cost-effectiveness. With this method, intricate designs, including gradients and photographic images, can be replicated with impressive detail. Additionally, DTF’s compatibility with a range of fabrics, such as cotton, polyester, and blends, enhances its appeal. As businesses seek innovative solutions for garment production, understanding DTF’s core principles becomes essential for maximizing its benefits.

Maximizing Efficiency with DTF Gangsheet Builder

The DTF Gangsheet Builder stands as a crucial tool for any printing operation looking to maximize efficiency and minimize costs. By allowing multiple designs to be printed on a single film, this tool not only reduces material waste but also optimizes the printing process. Each layout strategically combines different designs, which can significantly lower the expense per printed item. This is particularly advantageous for small to medium-sized production runs, where budgeting and resource allocation are key considerations.

To effectively utilize the DTF Gangsheet Builder, understanding the balance between design selection and layout is vital. Group similar designs to maximize the use of space while ensuring that there is enough margin for cutting and transfer. Furthermore, the ability to create cost-effective gang sheets can lead to improved business margins and quicker turnaround times, making it an indispensable aspect of modern textile printing.

Essential Tips for Effective Gangsheet Layouts

Creating effective gang sheets requires careful planning and attention to detail. The optimal layout is not just about fitting in as many designs as possible but ensuring that each design is well-placed to prevent issues during the printing process. It’s essential to use graphic design software that accommodates the dimensions of the film while preserving the integrity and resolution of each image. For best results, aim for at least 300 DPI to ensure sharp prints, even on fabric, where image clarity can be compromised.

Another critical tip is to incorporate a consistent theme or color palette across the designs to maintain a professional look. Group designs that resonate well together and avoid placing mismatched styles too closely, as this could confuse the final visual. By fine-tuning your gangsheet layout with these tips and utilizing tools like the DTF Gangsheet Builder, you can achieve a seamless transfer process and high-quality prints, elevating the overall output of your projects.

Color Management in DTF Printing

Color management is a pivotal component of effective DTF printing. Given the vivid and intricate nature of prints generated via DTF processes, accurately reproducing colors from design to final product is critical. Using compatible color profiles and ensuring your monitor is calibrated can drastically improve the consistency between what you see on screen and the final output.

Regularly testing prints on your fabric of choice is another best practice for ensuring that colors remain true throughout the production cycle. Variance in fabric type, texture, and even weight can affect color appearance once printed, so conducting tests is not only beneficial but essential for quality assurance in DTF printing.

Common Mistakes to Avoid When Using Gang Sheets

Even experienced printers can fall victim to common pitfalls when using gang sheets, which can compromise the quality of the final product. One significant mistake is overloading the gang sheet with too many designs. While the allure of maximizing print output exists, overcrowding can lead to dilution of print quality, affecting lines and details, which are crucial for intricate designs.

Another common error is neglecting the designated bleed areas. A lack of sufficient bleed can lead to unsatisfactory results, as any misalignment during the cutting process can leave white edges visible on the final fabric design. Always ensure that designs are extended beyond the intended cut lines to account for these potential discrepancies, providing a clean and polished appearance.

Valuable Resources for DTF Printing Enthusiasts

To support your DTF printing journey, there are numerous resources available that provide essential guidance and insights. Online communities, such as relevant forums on Reddit, can be treasure troves of information where users share their real-life experiences, troubleshooting techniques, and the latest trends in the DTF printing landscape. Engaging with these groups can enhance your skill set and keep you updated.

Additionally, blogs and educational websites like *Printavo* and *T-Shirt Magazine* offer extensive tutorials and guides tailored to both beginners and seasoned professionals. These resources cover everything from basic principles of DTF techniques to specific equipment recommendations, aiding you in implementing effective strategies for higher quality outputs.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing?

The DTF Gangsheet Builder is a specialized tool designed to optimize the Direct-to-Film (DTF) printing process by enabling users to combine multiple designs on a single film. This not only reduces material waste but also lowers printing costs while still delivering high-quality prints. By maximizing efficiency, it allows businesses to produce vibrant designs with ease.

What are some helpful DTF printing tips for using the Gangsheet Builder?

To effectively use the DTF Gangsheet Builder, ensure optimal layout by arranging designs to utilize the entire printable area, maintain a resolution of at least 300 DPI for sharp quality, and use proper color management techniques. Moreover, testing prints and using templates can save time and reduce errors, leading to highly successful DTF printing outcomes.

How can I avoid common mistakes when using a DTF Gangsheet Builder?

To avoid mistakes while using the DTF Gangsheet Builder, ensure to include sufficient bleed areas in your design, avoid overcrowding the gangsheet to prevent ink transfer issues, and familiarize yourself with your printer’s settings. These precautions will help maintain print quality and efficiency in your DTF printing process.

What types of designs are best suited for DTF printing with a Gangsheet Builder?

DTF printing with a Gangsheet Builder is ideal for intricate designs and vibrant colors on various fabric types. The method works well for small to medium-sized jobs, where multiple designs can be printed simultaneously without compromising on detail. Always ensure that designs are scaled appropriately for optimal clarity.

How does accurate color management affect the outcome of DTF printing with a Gangsheet Builder?

Accurate color management is crucial in DTF printing, especially when using a Gangsheet Builder. Utilizing compatible color profiles for your DTF printer and calibrating your monitor ensures consistent color reproduction across designs, ultimately leading to vibrant, high-quality prints on fabric.

What resources can help me improve my DTF printing skills and use the Gangsheet Builder effectively?

To enhance your DTF printing skills with the Gangsheet Builder, explore online communities like Reddit for shared experiences, and consult blogs such as Printavo and T-Shirt Magazine for in-depth tutorials on DTF techniques and equipment. These resources provide valuable insights and practical advice for achieving high-quality DTF prints.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A modern printing method that transfers designs from a film onto fabric using heat and pressure, allowing for vibrant colors and intricate designs without quality loss. |

| Understanding Gang Sheets | Gang sheets allow multiple designs to be printed on one sheet, reducing costs and material waste. |

| Tips for Building Effective Gang Sheets | 1. Optimal Layout: Use design software to arrange designs. 2. Sizing and Scaling: Maintain high resolution and adjust sizes. 3. Color Management: Use compatible color profiles. 4. Use of Templates: Utilize online templates to save time. 5. Testing: Conduct test prints to catch errors. |

| Common Mistakes to Avoid | 1. Neglecting Bleed Areas: Include a 0.125 inch margin. 2. Overloading the Gangsheet: Avoid overcrowding to prevent print issues. 3. Ignoring Printer Types: Be familiar with printer settings and requirements. |

| Resources for DTF Printing | Online forums, blogs, and tutorial sites provide insights and educational content for enhancing DTF printing skills. |

Summary

The DTF Gangsheet Builder is an essential tool for anyone looking to optimize their DTF printing process. By applying the tips for effective gang sheet construction, understanding the nuances of DTF printing, and steering clear of common pitfalls, you can enhance your productivity while achieving exceptional results in your designs. With the right knowledge and resources at your fingertips, the DTF Gangsheet Builder will empower you to elevate your textile printing projects and deliver impressive products that stand out in the market.