In the fast-evolving world of custom printing, the DTF Gangsheet Builder stands out as a revolutionary tool that is redefining how businesses approach their printing needs. This innovative technology leverages Direct-to-Film (DTF) printing methods, which allow multiple designs to be transferred onto fabric with remarkable efficiency. The DTF Gangsheet Builder not only streamlines operations but also significantly reduces the costs and waste associated with traditional printing methods like screen printing and direct-to-garment (DTG) processes. By embracing DTF printing technology, businesses can access sophisticated custom printing solutions that keep pace with today’s dynamic market demands. As we delve deeper into the advantages of DTF gangsheet builders, it becomes clear that they are leading the charge in transforming the landscape of the printing industry.

The advent of the DTF Gangsheet Builder signifies a pivotal shift in the realm of custom fabric printing. This cutting-edge solution, based on Direct-to-Film technology, empowers businesses to produce vibrant and intricate designs with ease and efficiency. When compared to conventional techniques such as screen printing and direct-to-garment applications, the DTF gangsheet approach presents a more cost-effective and versatile option for modern printing requirements. As industries continue to seek innovative printing solutions, understanding the benefits of DTF gangsheet builders becomes essential in navigating the ever-competitive landscape of custom printing.

The Evolution of DTF Printing Technology

The world of printing has significantly transformed with the advent of Direct-to-Film (DTF) printing technology. Unlike traditional printing methods such as screen printing, DTF introduces a streamlined approach to custom printing solutions. By utilizing specialized transfer films, DTF provides businesses with the capability to produce vibrant and durable prints efficiently. This technological evolution not only enhances the quality of printed materials but also reduces the operational complexity associated with older techniques.

Moreover, DTF technology stands out by allowing printers to produce multiple designs simultaneously on a single gangsheet. This significant leap over conventional screen printing and direct-to-garment (DTG) methods optimizes production workflows, particularly for businesses handling small to medium-sized orders. As DTF becomes more integrated into the fabric of modern printing practices, it is set to reshape how companies approach custom printing, making it an essential consideration for future operational strategies.

Comparing DTF and Traditional Printing Methods

When evaluating DTF gangsheet builders alongside traditional methods like screen printing and DTG, several factors come into play. DTF excels in its adaptability and efficiency; one of the primary benefits is the reduction in production time and material waste. Unlike traditional screen printing, which typically requires individual setups for each color and design, DTF allows for one print run of multiple designs, translating into significant cost and time savings for businesses.

However, traditional printing methods still hold merit, especially for high-volume runs where the quality and craftsmanship of screen printing shine. The tactile element of screen-printed garments appeals to many consumers, as does the rich pigment saturation that can be achieved in larger batches. In this context, while DTF may offer versatility and efficiency, businesses must balance these advantages against the established quality benefits of traditional methods.

The Cost-Effectiveness of DTF Gangsheet Builders

Cost remains a fundamental consideration for any printing operation, especially for small and medium businesses. DTF gangsheet builders emerge as a more economical choice compared to traditional screen printing techniques, primarily because they minimize setup costs and reduce material wastage. This ability to print multiple designs at once on a single film leads to lower overall production costs and improved profitability.

In contrast, traditional methods, such as screen printing, often require considerable upfront investment regarding inks, materials, and labor-intensive processes. Each design or color necessitates a separate setup, making it an uneconomical option for short runs or custom orders. As DTF technology continues to evolve, it promises to redefine cost efficiency within the custom printing landscape, allowing businesses to allocate resources more effectively.

Print Quality: DTF vs. Traditional Techniques

Quality of output is paramount in the printing industry, influencing customer satisfaction and repeat business. DTF printing has made great strides in delivering high-quality prints that rival those produced by traditional methods. The combination of advanced ink formulations and better transfer techniques allows DTF to produce vivid colors and intricate designs, which are essential for capturing the attention of customers.

Traditional screen printing, renowned for its durability, still offers a level of craftsmanship that is difficult to match. The vibrant results achieved in large batches make it a favorite among apparel manufacturers. Yet, as DTF technology advances, it continues to narrow the gap in terms of quality, giving businesses more options in choosing the best solution for their specific needs and enhancing their product offerings.

The User-Friendliness of DTF Printing Solutions

One of the key advantages of DTF gangsheet builders is their user-friendly nature. The complexity and skill required to operate traditional printing methods, like screen printing, can deter newcomers to the industry. DTF technology simplifies the printing process, allowing those with little experience to engage and produce high-quality prints with relative ease.

This accessibility not only democratizes the custom printing landscape but also accelerates the entry process for aspiring entrepreneurs. As businesses look to adopt innovative solutions, the ease of use inherent in DTF gangsheet builders becomes a compelling reason to transition away from traditional methods that can be cumbersome and require extensive training.

Environmental Impact of Printing Technologies

As sustainability concerns continue to rise, the environmental implications of printing methods are becoming increasingly prominent. DTF printing technology is positioned as a more eco-friendly alternative compared to traditional methods, such as screen printing, which often involves significant water usage for cleaning and mixing inks. The reduced need for water in DTF processes contributes to lower environmental impact, an essential consideration for today’s eco-conscious consumers.

Additionally, DTF gangsheet builders generate less waste material through their efficient printing systems. By enabling multiple designs to be printed simultaneously on a single film, DTF not only conserves resources but also decreases the carbon footprint associated with the production processes. As the printing industry strives for greener practices, DTF printing stands out as a leading option for companies looking to enhance their environmental responsibility while maintaining high-quality output.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it work?

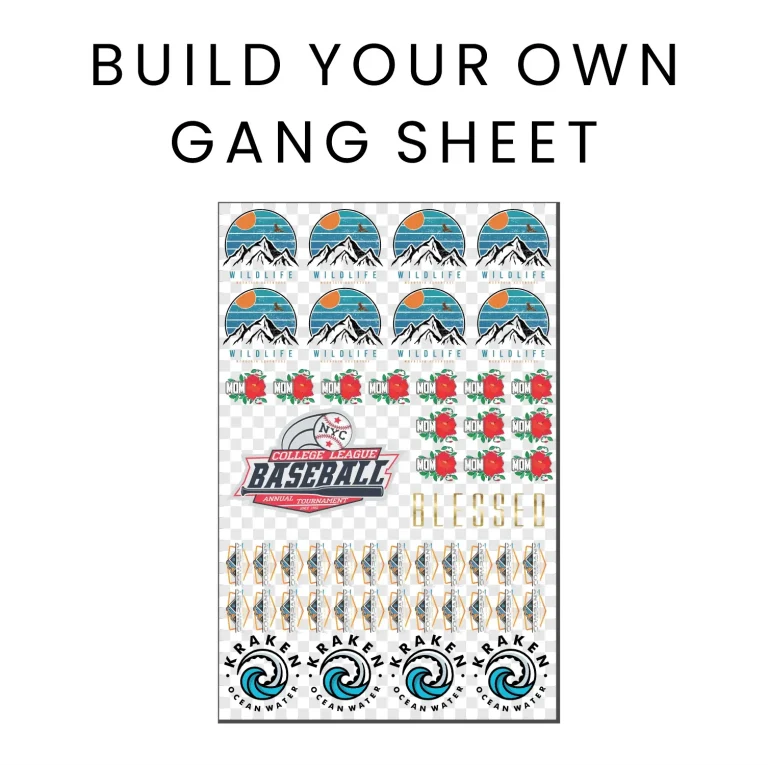

The DTF Gangsheet Builder is an innovative tool used in DTF printing technology, allowing multiple designs to be printed on a single transfer film. This process streamlines operations for custom printing solutions, making it ideal for small to medium-sized businesses by optimizing material use and reducing production time.

How does DTF printing technology compare to traditional printing methods like screen printing?

DTF printing technology, particularly through the use of DTF Gangsheet Builders, offers greater efficiency compared to traditional methods such as screen printing. DTF allows multiple designs to be printed at once, minimizing waste and setup time, while screen printing typically requires individual setup for each design, leading to higher costs and longer production times.

Can DTF Gangsheet Builders produce high-quality prints compared to Direct-to-Garment (DTG) printing?

Yes, DTF Gangsheet Builders can produce high-quality prints with vibrant colors and durability similar to Direct-to-Garment (DTG) printing. Advances in ink formulation and film quality enhance the output, making DTF a competitive option for intricate designs and color gradients.

What are the advantages of using DTF Gangsheet Builders for small businesses?

DTF Gangsheet Builders provide small businesses advantages such as increased efficiency, reduced material waste, and quicker turnaround times. By allowing multiple designs to be printed simultaneously on one sheet, it reduces production costs, offering a cost-effective solution that traditional printing methods cannot match.

Is it easier to use DTF Gangsheet Builders than traditional screen printing methods?

Yes, DTF Gangsheet Builders are user-friendly and generally require less technical skill compared to traditional screen printing methods. This accessibility makes it easier for newcomers to enter the printing industry, enhancing operational efficiency and reducing the learning curve associated with complex traditional techniques.

How do DTF printers address environmental concerns compared to traditional printing techniques?

DTF printing, especially using DTF Gangsheet Builders, is more environmentally friendly compared to traditional printing methods like screen printing. DTF technology uses significantly less water during the printing process and generates less waste, aligning with sustainable practices that many businesses are now prioritizing.

| Criteria | DTF Gangsheet Builder | Traditional Methods (Screen Printing & DTG) |

|---|---|---|

| Efficiency | Allows printing multiple designs on a single sheet, reducing setup time and material waste. | Requires individual setups for each design, leading to higher costs and longer production times. |

| Print Quality | Delivers vibrant colors and good durability, improving with advancements in technology. | Known for high-quality outputs, especially in large runs, but less versatile for intricate designs. |

| Ease of Use | User-friendly and accessible for newcomers with less technical skill required. | Requires extensive training and experience in color separation and other technical aspects. |

| Environmental Impact | Uses less water and generates less waste, contributing to sustainability. | Involves extensive water cleanup and generates more waste materials. |

| Market Trends | Growing adoption among small to medium enterprises for efficiency and versatility. | Established practices but facing competition from emerging technologies. |

Summary

DTF Gangsheet Builder is revolutionizing the custom printing landscape by offering unparalleled advantages in efficiency and cost-effectiveness compared to traditional printing methods. As detailed in our analysis, the DTF approach allows businesses to print multiple designs on a single sheet, thereby optimizing production times and reducing waste. Additionally, the user-friendly nature of DTF technology makes it accessible to newcomers, further highlighting its role in modernizing the industry. As more businesses seek sustainable and quality printing solutions, adopting DTF gangsheet builders is poised to become a strategic move. By embracing this innovative technology, businesses can enhance their operational processes, keep pace with market trends, and maintain a competitive edge in a rapidly evolving landscape.