UV DTF transfer is redefining how creators decorate mugs, jackets, and other everyday items with bold color and lasting detail, delivering vibrant gradients, sharp fine lines, and smooth color transitions that remain durable through regular handling, dishwashing where applicable, and repeated wear, all while keeping the process approachable for hobbyists, small studios, and even makers running weekend side projects, and inspires creative confidence in beginners trying new surfaces. By combining digital printing with a transfer layer and UV-curable inks, the method cures quickly, resists fading on challenging surfaces, supports a broad spectrum of substrates from ceramic mugs to coated fabrics, metal accessories, and plastic laminates, and integrates with common heat presses to fit compact workspaces while offering simple maintenance routines, removable liners, and scalable batch options for home studios and small shops. If you’re comparing DTF vs UV printing, UV DTF transfer on mugs can yield crisper lines and richer color on curved surfaces, while maintaining durability through reliable topcoats and proper curing, a workflow that scales from single-piece prototypes to small-batch production with consistent results across different inks, substrates, and design complexities. Whether you’re pursuing DIY UV DTF mugs jackets or other small-batch items, the technique plays well with UV printable fabrics and a heat press, offering a cohesive workflow across multiple product types, with predictable outcomes for color fidelity, edge sharpness, and adhesion on diverse surfaces, plus practical tips for testing on curved volumes, sample runs, and post-press care that extends the life of the print. For best results, follow heat press tips UV DTF to optimize temperature, dwell time, and pressure, while selecting appropriate laminates or topcoats to seal the print and extend life across mugs, jackets, and accessories, and incorporate color management steps, panel alignment checks, and mockups to verify fit and curvature before committing production runs.

In other words, this technique is a UV-curable digital-to-substrate transfer that blends high-fidelity artwork with practical durability, enabling vivid graphics to set quickly on ceramics, fabrics, plastics, and beyond. Readers may encounter related terms such as UV-curable ink technology, digital transfer films, or print-on-demand graphics, all pointing to a common principle of binding complex color to a variety of surfaces with a protective finish. From a Latent Semantic Indexing perspective, related concepts include substrate compatibility, cure speed, color management, texture, and workflow efficiency, which together help you plan projects that span mugs, jackets, and accessories.

UV DTF transfer: Essentials, Benefits, and Getting Started

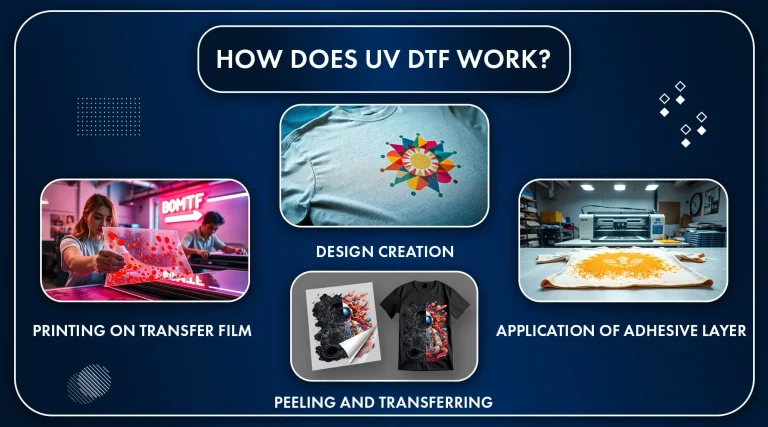

UV DTF transfer blends digital printing with a transfer layer using UV-curable inks, printed on a transfer sheet that is then applied to a substrate with heat and pressure. This method delivers rapid curing and strong color stability, making it well-suited for non-porous surfaces like ceramics, plastics, and metals, as well as UV printable fabrics. The result is sharp detail, rich color, and a durable finish that can be used for mugs, jackets, and a variety of accessories.

Getting started with UV DTF transfer means assembling a basic kit: a UV-curable ink printer or a compatible UV LED printer, transfer sheets, a heat press or mug press, and a recommended topcoat or laminate if your system calls for it. Practically, this approach supports a streamlined workflow from design to final product, enabling faster prototype-to-product cycles for DIY projects or small business runs. As you build experience, you’ll appreciate the ability to apply complex gradients and photographic elements across multiple substrates, including curved surfaces.

DTF vs UV Printing: How to Choose for Mugs, Jackets, and Fabrics

DTF and UV printing each have distinct strengths. DTF typically uses water-based inks on a transfer film and requires a heat press to move the image onto the surface, while UV DTF uses UV-curable inks that cure quickly for crisper lines and better color resistance. Understanding these differences helps you select the right method for a given project, whether you’re decorating mugs, jackets, or fabric items.

When deciding between methods, consider surface type, durability, and workflow. UV DTF tends to excel on mugs, bottles, and curved surfaces, providing rapid curing and solid color fidelity. For fabrics and UV printable fabrics, plan for appropriate topcoats and wash-care to maintain adhesion and finish over time, especially on items like DIY UV DTF mugs jackets that endure regular use.

Applying UV DTF on Mugs: Design, Print, and Cure

Design considerations for mugs include planning a wrap-around layout or a focused front graphic and testing alignment with mockups that reflect curved contours. Use high-resolution artwork (300 dpi or higher) and color-managed workflows to ensure sharp text and vivid photos when you print with UV DTF transfer on mugs. Testing on curved surfaces helps prevent white gaps and distortion once the transfer is applied.

Printing and curing should follow your system’s guidelines for proper adhesion. After printing, carefully cut the transfer close to the artwork, position it on the mug, and cover with a Teflon sheet before applying heat with a mug press or a flat heat press that can wrap around the curved surface. Finish with any laminate or topcoat as specified to protect the image from dishwashing or daily use, and remember to hand-wash when possible for longevity.

UV Printable Fabrics: From Jackets to Home Décor

UV printable fabrics open a path to durable, high-detail graphics on textiles used for jackets, bags, patches, and more. Start with pre-washed fabric and a clean surface to help adhesion, then design with fabric stretch and drape in mind. Printing onto UV DTF transfer sheets designed for textiles can capture fine gradients and sharp lines on fabrics, enabling bold garments and coordinated accessories.

On jackets and other apparel, plan for multi-layer designs and proper sequencing of heat and cure times to avoid delamination. Post-press care matters too: follow fabric care labels, turn garments inside out when washing, and consider a curing step if your transfer system recommends it for long-term durability on UV printable fabrics.

Heat Press Tips UV DTF: Achieving Consistent Results on Curved Surfaces

Temperature and time guidelines are system-specific, but a common starting range is 300–360°F (150–180°C) for 60–120 seconds. Begin with the manufacturer’s recommendations and run small test patches on your intended substrate. Consistent pressure is essential, especially on curved areas like mugs or jacket sleeves, so adjust pressure and verify repeatability across multiple samples.

In addition to temperature and time, focus on alignment and protective layers. Use Teflon or silicone sheets to prevent scorching and to preserve surface quality during heat application. For curved or irregular surfaces, plan your press workflow with mockups and ensure edges are flat enough to maintain even contact, then finish with the recommended topcoat or laminate when required.

DIY UV DTF Mugs Jackets: Creative Projects, Care, and Long-Term Durability

With UV DTF transfer, you can create cohesive design campaigns across mugs, jackets, and accessories, making it ideal for DIY gifts, small-batch collaborations, or personal branding. Use a shared motif or color palette to craft a recognizable line of items for events, gifts, or shop-ready products, leveraging the durability and detailed color that UV DTF delivers.

Care and longevity matter as your projects move from design to daily use. For fabrics, follow cold-water washing, inside-out loading, and gentle handling to preserve color and adhesion. For mugs and hard surfaces, hand-washing is often recommended unless your transfer system is rated for dishwashers; if you use a topcoat or laminate, ensure proper curing and inspect edges periodically to prevent peeling or cracking.

Frequently Asked Questions

What is UV DTF transfer on mugs and how does it compare to DTF vs UV printing?

UV DTF transfer on mugs uses UV-curable inks printed on a transfer sheet and cured quickly for bright, durable images. Compared to traditional DTF printing, UV DTF offers crisper lines and faster production due to rapid curing, while UV printing applies ink directly to a surface. For mugs, this combination delivers vivid color stability and strong adhesion when the correct topcoat is used.

Is UV DTF transfer suitable for mugs, jackets, and other surfaces, including UV printable fabrics?

Yes. UV DTF transfer is versatile enough for ceramic mugs, jackets, and a wide range of UV printable fabrics. Proper surface prep and compatible heat-press settings are key, and you can add laminates or topcoats to enhance durability on fabrics and hard surfaces.

What heat press tips UV DTF should I follow for successful transfers?

Follow the transfer system’s guidelines; typical ranges are 300–360°F (150–180°C) for 60–120 seconds with consistent pressure. Use Teflon or silicone sheets to protect surfaces and test on curved surfaces like mugs to prevent distortion. Adjust pressure and time for each substrate to improve adhesion and color fidelity.

How do I apply UV DTF transfer on mugs for a DIY UV DTF mugs project and what surface prep is needed?

Start with a clean, dry mug and test alignment using a mockup. Print and cure the design on UV DTF film, then cut closely and place on the mug. Use a mug press or curved flat press with a Teflon sheet, apply heat and pressure, then cure the finish or topcoat as required.

What are the best practices for caring for UV DTF transfers on jackets and UV printable fabrics?

Care by washing inside-out in cold water and avoid high-heat drying; iron on the reverse if needed. For jackets, follow the fabric care label and apply a recommended topcoat if provided. For UV printable fabrics, handle with gentle cleaners to preserve color and adhesion.

What common problems occur with UV DTF transfer and how can heat press tips UV DTF help troubleshoot?

Common issues include fading, peeling, and misalignment. Ensure proper curing, surface prep, and compatible laminates. Using heat press tips UV DTF to tune temperature, time, and pressure and running test patches helps identify the best settings before production runs.

| Aspect | Key Points |

|---|---|

| What is UV DTF transfer |

|

| UV DTF transfer vs traditional methods (DTF vs UV printing) |

|

| Why choose UV DTF for mugs, jackets, and accessories? |

|

| Surface versatility |

|

| Materials and tools you’ll need |

|

| Design considerations: color, surfaces, and layout |

|

| UV DTF on mugs: a practical how‑to |

|

| UV DTF on jackets and fabrics: a practical how‑to |

|

| Heat press tips for UV DTF projects |

|

| Troubleshooting, durability, and care |

|

| Creative ideas and the DIY mindset |

|

| A note on durability and care |

|

Summary

Conclusion

UV DTF transfer is a game‑changer for creative projects, especially when you want bold, accurate graphics on mugs, jackets, and accessories. By understanding the differences between DTF vs UV printing, identifying the right UV printable fabrics and materials, and following careful heat‑press practices, you can produce professional‑looking results at home or in a small studio. Experiment with designs, test on different substrates, and soon you’ll be crafting a whole line of personalized items that stand out for their color, detail, and durability.